Many “global historians” argue that the British cotton industry was the product of (unintentional) infant industry protection from Indian competition in the 18th century. The various Calico Acts created an import-substitution industry by banning Indian cloths and reserving the home market for British producers. This supposedly gave them the freedom to invent and adopt the machines that led to the Industrial Revolution.

To the best of my knowledge, economic historians have never seriously examined this issue, perhaps because the necessary data are lacking or remain unearthed. Nonetheless there are sound historical reasons for doubting the presumption that “protection allowed British goods to become competitive”.

Warning: This is a tedious post which gets into some detail about the British textile industry in the 18th century. A must-skip, if you ask me. Which is why I provide this handy summary:

- The Calico Act of 1721 (which was intended to protect the wool and silk industries) actually banned most varieties of pure-cotton cloths in general, not just Indian.

- Before the era of mechanisation, British ‘cotton’ was overwhelmingly cotton-linen, a limitation of British technology (in the economic sense).

- Mainstream economic theory supplies many justifications for interventionist trade policy to promote innovation. But the standard rationales simply do not apply to constant returns-to-scale activities such as handicraft cottage industry.

- Lancashire would have survived competition with Indian cloths in an unprotected home market.

- British machine-spun yarn never faced any direct foreign competitor, since Britain barely imported cotton yarn in the 18th century. The domestic output of yarn was affected by foreign competition only to the extent that it was turned into printed cloth.

- But there were many other products besides British imitations of Indian cloth which used cotton yarn as a major input, and their role in the mechanisation of yarn production is overshadowed by a selective, Whiggish genealogy which overemphasises the calico branch.

- IF, as so many argue, competition in the export markets was an important stimulus to inventions in cotton, then the home market could have served just as well and the only reason overseas became so important is that British firms were denied a home market for all-cotton cloths by the Calico Acts!

- Therefore, it’s entirely plausible — not demonstrated — that the Calico Acts functioned as a Luddite policy which delayed the mechanisation of textile production by decades.

This post elaborates on the above points, covering the period up to 1774, when the Calico Act was repealed.

The Calico Acts

In the 17th century, the various East India Companies started importing cotton and silk fabrics from Asia which were printed with beautiful and intricate patterns. The fine, hand-painted cotton cloth from India was called a ‘calico’, after Calicut, although we might call it chintz today.

The ensuing “calico craze” shifted some demand away from Europe’s well-established wool and silk industries, which screamed for relief from their governments. In Britain, agitation over the course of several decades induced Parliament to enact a series of protective measures culminating in 1721 with an outright ban on most varieties of printed cottons, whether foreign or domestic. The target was not merely Asian goods but potential substitutes for silk and worsted.

I reiterate: the second so-called Calico Act of 1721 (7 Geo. I) prohibited the “wearing or using in apparel, household stuff, or furniture, … any stuff made of cotton or mixed therewith, which shall be printed or painted with any colour or colours, or any calico chequered or striped…” (There were a few exemptions, the most important being the superluxurious muslins from India. See the statute.)

The gory, tangled details of the politics behind the Calico Acts are brilliantly narrated in Griffiths, Hunt, & O’Brien (1991), but here are some relevant bits:

- Exports: You could still manufacture the banned cloths for export to foreign and colonial markets, or print imported white cloths in London but only for re-export.

- Linen: There was an ambiguous loophole for cotton-linen blends, which was made explicit in 1736, and these became the material of choice for printing cloths in Britain.

- 1774: The ban on printed cottons was repealed.

- After 1774, and until the 1820s, Indian imports continued to face stiff duties, ranging from 27-59% ad valorem in 1803 to 71-85% in 1813 [Ray 2009]. But this is something usually only Indian historians bother to mention, and I have treated this issue in a separate post.

The rise of British cotton as industrial policy?

It’s peculiar to argue that a product ban should promote the domestic manufacturing of that banned product.

Yet surprisingly many do credit the Calico Acts with {accidentally} stimulating cotton as an import substitution industry in Britain. Parliament may have intended to benefit wool and silk, but cotton ended up the beneficiary nonetheless. This idea has been around for more than a century, but is newly popular with authors who stress the role of industrial policy, political contingency, and “global connections” behind the Industrial Revolution, such as Ashworth, Beckert, Chang, Marks, Moe, Vries, countless Indian writers, etc. To be fair, most of these mention the idea largely in passing, as a throwaway en route to their larger point. Some of them, however — especially Beckert and Chang — garble the story and do not seem to realise the ban applied to cottons in general.

But Parliamentary “industrial policy” becomes a key element of the narrative about why British cotton emerged as a globally dominant industry in three works:

- Inikori, Africans & the Industrial Revolution in England;

- Parthasarathi, Why Europe Grew Rich & Asia Did Not;

- Griffiths, Hunt & O’Brien (1991), “Political components of the industrial revolution: Parliament and the English cotton textile industry, 1660-1774”.

Both Inikori and Parthasarathi stress the combination of domestic protection and overseas competition. The captive home market gave British manufacturers of cotton-linen ersatz the higher rents and the freedom to experiment at home, facilitating the “development of skills, technology and markets” [Parthasarathi]. At the same time, there was rising demand in the overseas markets secured by mercantilism and imperialism for fabrics of the types made in India and marketed by the East India Companies. Thus, British firms engaged in “protracted competition” abroad with Indian textiles which “stretched their ingenuity to be equal to the fight” and “induced them to adopt cost-reducing and quality-raising innovations” [Inikori].

Inikori leans heavily on his reading of the development econ literature from the 1970s, especially Balassa. The way he sees it, 18th century England practised a policy of import-substitution industrialisation, kind of like … Latin America before the 1980s. But unlike the inward-looking ISI, England managed to avoid industrial stagnation through an “export push”, kind of like … East Asia.

In keeping with historians of consumption like Maxine Berg and Beverly Lemire, Parthasarathi also puts tremendous emphasis on the development of the domestic capability for finishing and printing of cloth in emulation of the intricate patterns and bright colours of Indian cloths. Cotton took to colours better than any other material at the time, and in Europe’s first consumer age with a taste for expanding product varieties, a large portion of the value added of cloth was their look and finish. Since Indian artisans were more advanced in dyes and mordants, the British textile printing industry faced a steep learning curve which might have required protection.

Complementary to the above is the argument in the paper co-authored by the venerable British historian Patrick O’Brien (1991). The “legislative foundations” were just right in Britain, neither as restrictive as the total ban on printed cottons and linens in France [Rouen excepted]; nor as permissive as the free-for-all in the Dutch Republic. So Parliament, by reserving the home market, made the size of the British proto-industry bigger than it would have been otherwise. And “technological innovation and reorganization become more probable once industries attain critical scales of production and experience”.

O’Brien et al. do not elaborate much, but at the simplest level, their argument could be taken to mean the “R & D sector” faced a larger domestic market for inventions and therefore more profit opportunities for inventors. It could also imply the size of the domestic industry generated more collective learning, economies of scale, and agglomeration economies.

All these propositions seem reasonable at first sight, but there are some basic problems.

The Linen Caveat

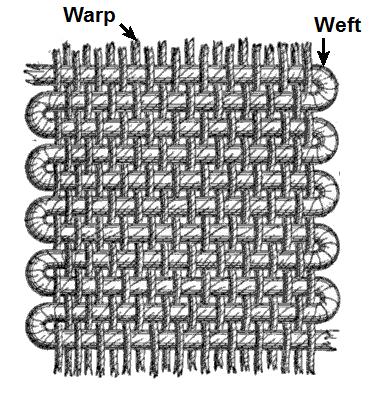

Even before the 1721 legislation, Britain (and Europe in general) produced almost no pure-cotton cloth. Cotton had been primarily a material used to blend with linen in a traditional class of heavy, often textured fabrics called fustians, which might be considered the common ancestor to denim, velvet, corduroy, moleskin, etc. (This term is often confused with anything that’s half-cotton, half-linen, but in this post ‘fustian’ refers to the heavy article.)

Until the 1770s, lightweight British ‘cottons’ made in imitation of Indian cloth, with names like calicos, stripes, and checks, would also be cotton-linen even in the export markets. The reason was a technological constraint: European hand-spinners could spin only cotton weft at manageable cost, not warp; and ‘cotton’ weavers substituted linen thread for the warp.

Hargreaves’s spinning jenny, though considered the first of the canonical cotton-related inventions of the Industrial Revolution, could only make the loosely spun weft. It took Arkwright’s water frame to produce the tightly wound warp with cotton. Only then could an all-cotton cloth be woven in Britain at less-than-astronomical cost.

Hargreaves’s spinning jenny, though considered the first of the canonical cotton-related inventions of the Industrial Revolution, could only make the loosely spun weft. It took Arkwright’s water frame to produce the tightly wound warp with cotton. Only then could an all-cotton cloth be woven in Britain at less-than-astronomical cost.

None of this is esoteric knowledge. Although a reader will never learn it from Beckert’s oppressively information-dense Empire of Cotton, British reliance on cotton-linen blends prior to mechanisation is widely noted in the literature, e.g., Parthasarathi himself; Riello, Harley (1998), and Wadsworth & Mann, the cited-by-everybody proto-industrial history of Lancashire. Also, Styles (2016) reports a microscopic fibre content analysis of Lancashire swatches from 1759-60, confirming that ‘cottons’ for ordinary people were indeed linen blends. {For the Styles paper, sombrero tip to Anton Howes, who could not anticipate the dastardly uses I would put it to.}

So, on the face of it, the Calico Acts reinforced the preexisting ‘backward’ technology of cotton-linen. But there’s even more.

- Printed cotton-linen was subject to discriminatory excise taxes which could be as high as 25% of the price for the cheapest cloths. [Wadsworth & Mann, pg 140]

- Although Lancashire depended on imported linen yarn to produce substitutes for Indian cloths, Parliament made that key input more scarce and expensive by subsidising the weaving of linen cloth in Ireland and Scotland. [O’Brien et al. 2008]

White cotton cloth was never banned, but there was hardly any market for it, since British preference in shirts, shifts, bedsheets, and undergarments did not switch from linen to cotton until the 19th century. More fragile cotton had to become cheap enough before overcoming linen’s chief advantage: you could beat the crap out of it in the ‘brutal’ washing methods of the time. [Styles 2009]

A common-sensical first approximation is therefore that the effect of Parliamentary legislation was to discourage British cotton which emerged in spite of legal hindrances.

Economic historians & industrial policy

But that doesn’t stop Parthasarathi from offering his 2 cents (or 2 paise in his case) on the anti-empirical dogmatism of economists:

It is a bedrock conviction of mainstream economics that restrictions on trade are harmful and reduce economic efficiency and social welfare. This belief has led many economic historians to downplay the role of protection in the development of British cotton manufacturing.”

“Robert Allen’s British Industrial Revolution in Global Perspective, for instance, contains no discussion of restrictions on Indian cloth and Joel Mokyr’s Enlightened Economy dismisses protection on the grounds that it was rent-seeking rather than value-creating. The historical record, however, does not support these views, and the protectionist response to the Indian competitive challenge facilitated the development of skills, technology and markets, which were a precondition for the growth and expansion of the British cotton industry”.

Given the smugness of the last sentence I would normally start spitting venom, especially since Parthasarathi’s book supplies a mere narrative description which he falsely equates with causal analysis. But I calmly point out that economic historians actually keep an open mind on the matter.

Allen himself — indicted in the passage above — has shown sympathy for infant industry arguments in several publications (e.g., 2011, 2014). Parthasarathi might also have perused the research on the “growth tariff paradox” of the late 19th century. Or the debate on the role of antebellum tariffs in US economic development, much of which focuses on cotton! Not to mention, a rich body of theoretical literature on industrial policy and “dynamic comparative advantage” has existed for the past 25 years at the intersection of endogenous growth theory, strategic trade theory, and economic geography. (I describe the various classical and modern arguments for infant industry protection here.)

But do the standard rationales for protection apply under 18th century British conditions?

Probably not.

Most of the standard theoretical rationales are inapplicable and anachronistic for traditional handicraft manufacturing. The size of the cotton-linen proto-industry was not important. It generated little technical learning which would spill over to the future cotton industry. And the market for cotton-related inventions was quite large even without the industry making substitutes for Indian cloth.

(a) No scale in the cotton-linen proto-industry

Under the putting-out system for textiles, terms like ‘industry’ or ‘firms’ can be misleading, because the ‘manufacturer’ was basically an organiser of handicraft production taking place inside rural hovels.

In this system, capital costs and the minimum efficient scale were laughably low. According to Muldrew (2012), a spinning wheel cost only about a shilling, equivalent to 2-3 days’ worth of spinners’ earnings. Even the spinning jenny, conventionally considered a major step in mechanisation, was still just a domestic hand-powered implement which happened to make more than one spindle of yarn at a time. Although in Allen’s analysis the jenny cost ~70 shillings, more realistically it may have cost only 16-20 shillings. Compare that with a thousand pounds for the early Arkwright-style spinning factories in the 1790s.

By the same token, putting-out was also a constant returns to scale activity. There were no economies of scale to exploit, which is to say, the overall size of production in proto-industry, per se, did not matter to unit costs or productivity. This also rules out the “East Asian” or “late 19th century steel” model whereby firms exploited scale in the protected domestic market and turned to exports after their average cost was sufficiently reduced.

Likewise, in proto-industry, barriers to entry were low and there was little first-mover advantage. By implication, even if Indian competition had wiped out British cotton-linen cloth (say) in the 1730s, you could easily reenter the industry at a later date (say the 1750s, when war and unrest in India reduced the global supply of cloth).

(b) Lancashire would have survived open competition with India in the home market.

It might have had a smaller market share in printed cloths, but linen or cotton-linen knock-offs would have coexisted with higher-quality Indian cloths as differentiated products in a segmented market, kind of like the iPhone and cheap smartphones. British proto-industry would have strategically adjusted the fibre content of their cloths according to market conditions. This is not some idle, far-fetched speculation, as it actually happened in West Africa and the mainland American colonies in the 18th century, where British cloths competed with Indian textiles. It’s also suggested by the (admittedly patchy) price evidence on the British side, and the better documented trend of rising purchase prices of Indian cloth by the British East India Company. Riello also suggests, “in the period of the prohibition of cotton textiles, high prices – rather than legal zeal – might have hampered the use of Indian chintzes and calicoes in England”. (I elaborate in the comments section.)

(c) Learning & source of knowledge externalities

There was no learning-by-doing in the cotton-linen proto-industry which especially mattered to the mechanisation of cotton production. There were product innovations, and there were (probably) gains from fibre-specific learning and from the division of labour in hand processes. But cotton had already been used as a blending input in traditional products. So it’s not clear that the extra activity specifically promoted by the Calico Acts — i.e., more hand-spinning of cotton weft and hand-weaving with linen warp — was terribly consequential for mechanisation.

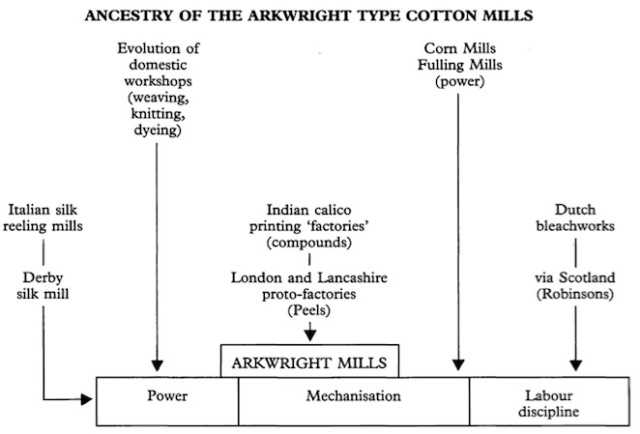

Simply as a matter of historical fact, many of the advances in mechanising cotton production were knowledge spillovers from industries whose products were unrelated to the import substitution industry for Indian cottons. Things like steam engines as well as what Mokyr (1990, 2012) called Britain’s comparative advantage in mechanical skills are well known. But there are many less well known transfers of knowledge to the cotton industry from millwrights, metallurgy, watch-making, and other textiles such as wool and silk. I put the details in the comments section, but here’s a neat ‘map’ of the externalities from Chapman (1992):

{ Textile printing, which was indeed capital-intensive and required substantial learning-by-doing, was an exception. Again I relegate this to the comments section.}

Competing versus non-competing sectors of British ‘cotton’

During most of the 18th century, branches of the British ‘cotton’ industry which did not compete with Indian goods were much larger than the ‘competing’ sector. The non-competing sector grew rapidly until the 1770s and demanded more and more cotton yarn. These diverse uses of cotton fibre and yarn afforded ample profit opportunities and incentives for the invention and adoption of spinning machines.

(a) How big was the ‘cotton’ proto-industry anyway?

In the early 1980s, Harley (1982) and Crafts (1983) famously published their downward revision of British GDP growth in the ‘critical’ 1770-1840 period. The most important element of the ensuing debate was about the size of the cotton industry. (See Cuenca-Esteban 1994 & Harley 1998, and a literature’s worth of replies in-between.)

According to Crafts, as late as 1770, cotton as a whole represented ~2.6% of value added in British industry. Silk was almost double the size; and linen, more than three times. But cotton was completely dwarfed by wool, which was 12 times bigger. Thirty years later, cotton and wool would be neck-to-neck.

One thing was highlighted in the debate: there is surprisingly little hard quantitative information about the cotton industry even during the Industrial Revolution. The period before the 1770s might as well be a black hole. For example, we can infer the cotton industry’s aggregate gross output only very crudely, by making assumptions about how the imported raw cotton input was transformed into output in 1698-1770s.

That may be adequate for computing GDP estimates, but it doesn’t help with micro issues — such as, how were those fibre imports distributed amongst the diverse uses of cotton? We can’t precisely answer this question, even though there was a dizzying variety of cotton-containing products with quite different values added.

(b) The diverse uses of cotton in proto-industry

But we do know one thing: the non-competing branches of the British ‘cotton’ industry prior to mechanisation were larger than the ‘competing’ sector. Besides the part-linen checks, stripes, and imitation-calicoes that served as Indian substitutes, Britain’s other cotton-consuming sub-sectors included:

- fustians — a catch-all term for heavy fabrics associated with Manchester, including velvet, velveteen, corduroy, ticking (upholstery fabric), etc.

- ‘smallwares’ (tapes and ribbons for garters, etc., also associated with Manchester)

- hosiery & lace (associated with the Midlands)

We don’t know exactly how big each of these ‘non-competing’ sectors was, or which sector was growing at what rate in the mid-18th century. I’m sure it’s possible to work like a donkey in the excise & customs archives and probate inventories to gather the necessary data for estimating the proportions. But to the best of my knowledge no one has done it.

But we can still deduce from published data on excise duties that the India-competing sectors of cotton as a whole accounted for a maximum 17% of the raw cotton imported in 1765 — but more likely 10%. (The details of the back-of-the-envelope calculation are relegated to comments.)

10-17% is not trivial, especially if printed textiles had faster growth rates or disproportionately high value added. But the non-competing ‘cotton’ branches like fustians and hosiery also had high value added. In the years after the Napoleonic Wars, Harley (1998) estimated that the hosiery sector accounted for 7-10% of cotton yarn by weight but 1/3 of the value added in spinning. Earlier in the 18th century, hosiery might conceivably have been bigger, since yarn and cloth output expanded rapidly after 1790.

And fustians, smallwares, and hosiery were technologically dynamic sectors with a spurt of inventive activity in product innovations in the mid-18th century (Griffiths et al. 1992). Hosiery had the Derby Rib as well as the stocking frame with rotary motion. Smallwares had beginnings of factory organisation with the swivel loom.

J. K. Thomson describes fustians in the mid- to late 18th century:

The industry in Lancashire was in full expansion during the years of [Lewis Paul’s] efforts [to invent a spinning machine], with progress being logged in two spheres in particular, that of checks and cottons for Africa, whose exports multiplied by six between 1752 and 1763, and that of fustians [my emphasis] in which a steady process of product innovation in patterns, finishes and fibre mixtures had been occurring. Milestones here were the introduction of the drawboy loom [a precursor of the Jacquard loom — PE], facilitating complex weaving patterns and the development of pure cotton thicksets, introduced before 1740; cotton velvets, introduced soon after this; veleverets, 1763; and velveteens, ‘incomparably the most important development in the middle of the century’ (Mann), patented in 1776. The tendency has been to give prominence to the meteoric expansion in cotton stripes and checks among these developments but this may be mistaken, firstly insofar as their growth led to few technical improvements in spinning … and secondly in that this growth was reversed from 1763. The developments in fustians, in contrast…did depend on significant technical improvements, in spinning as well as weaving”. [Thomson in Prados de la Escosura, ed. 2004]

The so-called “Manchester velvets” — as far from anything to do with India as possible — became a prized item in Europe after the 1750s. These were hot enough that a Jacobite spy for the French, John Holker, supposedly risked his life to secret its manufacturing methods out of England [Rose pp 190-1].

The importance of the non-competing sectors is also suggested by the distribution by Arkwright-type (first genuinely automated, water-powered) spinning mills in 1787-8:

[Source: Chapman (1981); also see map of the above data.]

Before cotton firms agglomerated in Lancashire, the availability of water power was a major determinant of factory location. But the map also speaks to the diverse final uses those factories served. Only about a quarter of the Arkwright-type spinning mills were located in Lancashire, and of those only a handful in towns associated with weaving for calicoes, such as Blackburn.

(c) The Neglected Role of the Midlands

Despite the obvious importance of the non-competing sectors, strong and confident assertions are made about the Calico Acts, because it is just assumed anachronistically that Britain’s domestic import substitute for Indian cottons is the only relevant thing to consider.

The size and importance of the non-competing sectors of cotton implies that British cotton spinners per se never faced much foreign competition at all. Britain imported almost no cotton yarn (Hoffmann pp 255-7); and yarn has competitors only insofar as it is turned into competing cloth.

So even if Indian cloths wiped out British imitations in the home market, the fustian, smallwares, and hosiery sectors would have merrily gone their way churning out other stuffs with cotton yarn. They would have demanded more and better yarn from domestic sources. And, had there been Indian competition in a fully open British market, even more capital would likely have been allocated toward the ‘non-competing’ sectors in order to exploit Britain’s comparative advantage.

Again, this is no fanciful speculation, as the actual historical record shows the two great inventors of the Industrial Revolution hagiography — Hargreaves and Arkwright — were initimately connected with the Midlands hosiery industry.

Every scholar has his hobbyhorse “big thing” when it comes to why spinning was mechanised: it’s high wages; it’s low wages; it was legislation; it’s the African trade; it’s the American trade; it was fashionable prints; it was to match Indian quality and skill; it was the rising demand for yarn from the flying shuttle; etc.

But nobody ever nominates stockings in Nottingham!

Arkwright, whose game-changing water frame finally allowed British weavers to abandon linen yarn and make an all-cotton cloth, removed to Nottingham around 1769. There he received financial backing from Need and Strutt, two manufacturers of stockings from Nottingham and Derby. (Strutt himself was the inventor of the aforementioned Derby Rib, a loom for stockings.)

Hosiers in the Midlands had been using wool and silk, but after mid-century they were increasingly substituting cotton for silk and sometimes importing expensive Indian yarn. Arkwright sought to alleviate the shortage of tightly twisted cotton yarn for the hosiers and the first water-powered spinning mill with his frame was built at Cromford (in Derbyshire).

Indeed Strutt and many other hosiers eventually became cotton spinners — all the incestuous connections are pictured below:

[Source: Chapman 1974]

Hargreaves, the inventor of the spinning jenny, had been a Lancashire weaver in the employ of Peels, the manufacturer of cloth for calicoes, but the machine-breaking riots of 1768 “induced Hargreaves to accept an offer from Rawson, Heath and Watson, the Nottingham hosier” [Chapman 1969] and he “continued his development between 1764-67 in Nottingham in partnership with a local joiner, one Thomas James” [O’Brien]. Hargreaves himself constructed a mill with financing in Nottingham and supplied the local hosiers with yarn from his jennies.

None of these Midlands connections is esoteric information, but something widely mentioned in any source of information about the early Industrial Revolution. (Baines pp 161-3; 339-45; Fitton; Wadsworth & Mann pp 483-5; Crouzet; Thomson in Prados de la Escosura; Chapman 1965, 1972, 1987).

But the fact that Arkwright went on to become a manufacturer of calicoes and muslins (and petitioned Parliament to repeal the 1774 law) has completely overshadowed his important links with the hosiery trade.

( Hargreaves’s spinning jenny and Arkwright’s water frame were eventually even adopted in woollens and worsted, respectively. [See Hudson; Chapman (1965)] )

Innovation & export competition

Many scholars ranging from Inikori and Parthasarathi to Allen and Findlay & O’Rourke have argued that export markets were an important stimulus to technical innovations for the British proto-industry. For some of these, exports increase the size of the potential market for firms. For others, overseas markets exposed firms in a protected domestic market to healthy competition. But which ever is your theory, the home market could have served these purposes just as well.

This is not necessarily true for nascent industries struggling with modern technologies, high fixed capital costs, increasing returns to scale, etc. These might, in theory, need “breathing space” from more efficient foreign producers. But this “breathing space” was likely unnecessary in the case of the cotton-linen proto-industry in the British industrial revolution. This conclusion follows in the absence of scale economies or significant learning or major barriers to entry.

I am not saying exporting was irrelevant — the lure of profits through competition with Indian goods in West Africa and the mainland American colonies may have been in actual historical fact a major incentive for British entrepreneurs. But the reason export markets became so important in the first place may be that British firms were denied the chance in the domestic market to supply all-cotton cloths by the Calico Acts !

Why wasn’t the jenny invented in the 1730s rather than in the 1760s? It’s not a very sophisticated machine and one might argue its invention was inevitable given the right market conditions. And there were early attempts by Paul and Waytt to build a spinning machine on different principles in the late 1730s, but those did not succeed commercially.

One possible reason is that the Calico Acts diminished the size of the potential market for pure-cotton cloths by excluding the home market, and successful inventions in cotton spinning were deferred until population growth enlarged the export markets:

The growth of British exports can be almost entirely explained by population growth in North America and naval successes that opened markets in the Spanish and Portuguese colonies to British trade. From 1730 to the end of the century three quarters of the increase in exports went to North America and the West Indies, and more than four fifths of the spectacular export growth from 1770 to the end of the century went to those markets. The growth of exports to North America was almost entirely a reflection of population growth there. Between 1710 and 1770 British exports to North America increased to 8.6 times their initial level as American population increased to seven times its initial level”. (Harley 1982)

So Parthasarathi is right to say economic historians ignore the Calico Acts. Maybe they can help explain the timing of the industrialisation of cotton!

§ § § § §

Of course many (such as the very good historians, O’Brien, Ashworth, and Vries, but also Erik Reinert a lesser twin of Ha Joon Chang) might argue it was not the protection of any single industry but the whole ‘structure’ of mercantilism and imperialism which pushed Britain toward the Industrial Revolution. Even Parthasarathi, though single-mindedly focused on cotton, has a brief digression on iron. The silk industry which contributed technology to cotton was itself an object of mercantilist promotion and interstate competition. So what’s really needed is a model of the Industrial Revolution which endogenises innovation in terms of the factors alleged to be partly causal, such as war, mercantilism, colonialism, and slavery. But the argument that the Calico Acts were an important factor behind the mechanisation of cotton, seems misguided.

Postscript: In the comments section, I put some details I left out above:

- pounds of cotton consumed by printed textiles

- prices & market shares of British & Indian cloths

- textile printing

- knowledge externalities

- miscellaneous stuff

Also: there’s a separate post about tariff protection for British cotton after 1774, with a note on the hand weavers.

Pounds of cotton consumed by the printed textile sector

In 1765, approximately 6.4 million yards of cloth — including silks, pure linens, fustians, and calicoes — were levied excise taxes (Mitchell). Assuming 1 lb of cotton = 5 yards of cloth which is the lowest figure used by Crafts & Harley (1992, app. 2), and halving that for 50% linen composition in ‘cotton’ cloths, the excised textiles were equivalent to ~650,000 lbs. of yarn. Per Mitchell, Britain imported ~3.8 million lbs. of raw cotton in 1765. Therefore, with many upward biases added in, the sector producing printed ‘cottons’ accounted for maximum 17% of British industry’s use of raw cotton as an input in 1765.

This is a very crude calculation, but it should be considered an upper bound and it’s probably closer to 10% if you subtract linens, silks, and fustians. That’s plausible given the estimates made for later dates. According to Harley (1998), in 1818 “[b]y weight, printed calicos accounted for some 15 per cent of the yarn spun”.

The 10% figure is also believable because domestically, imitation-calicoes would have had relatively limited uses, such as “frocks, aprons, quilts” and furnishings like curtains (W&M pg 133).

By the way, the 10-17% figure refers to total production including exports and domestic consumption. It’s possible to infer domestic consumption from ‘drawbacks’, as excise duties on exported goods were rebated (Ashworth p252).

The same calculation for the entire period 1721-74 yields the following:

So we can say 75-90% of the imported raw cotton was used in non-competing sectors of British ‘cotton’ at any given time in the period 1721-74. But there’s definitely a trend for increasing output of printed textiles. (Again, these include silks, pure linens, and fustians, partly to bias the result against my view, but also because I don’t have the data to separate those out.)

LikeLike

The Multi-Fibre Agreement was set up as a modern, more sophisticated way of shafting the poor countries. For example, I could buy a yak lamb’s wool sweater in Kathmandu for £5, because they were not allowed to export them to the rich countries. Davao in the Philippines found a loophole, one product not regulated, so had a plan to become the world’s biggest producer of ladies’ underpants.

LikeLike

Could Lancashire have survived free trade with India?

There is no consistent time series of cloth prices before the 1770s-80s. What Harley 1982 called the “bewildering array of fabrics and nomenclature” produced by both Lancashire and India, not to mention unknown changes over time in quality, fibre count, weight, and non-standardised quantity units, pose one motherf***ker of an index number problem.

But the scattered evidence suggests that British cotton-linens were cheaper than Indian calicoes. Prices of the heavy fustians — different from the light cloths which would have competed with India but of the same cotton-linen composition — were quite low in the 17th and 18th centuries.[Source: Parthasarathi extracted from Shammas]

The price differential between fustians and calicoes was much greater than can be accounted for by import duties in effect before the 1721 ban. Since calicoes were banned in Britain between 1721 and 1774, here are prices from Massachusetts, where East India Company goods entered freely as British reexports from London:

[Source: Shammas 1990]

Of course, without the Calico Acts, the East India Company might also have imported India’s lowest-price-point “Guinea cloths” from Gujarat to compete with Lancashire checks and stripes in the British home market. As far as I know, prices of Guinea cloths haven’t been extrapolated from the East India archives and published, but Inikori‘s Table 9.8 gives us hints about British and Indian market shares in West Africa:

Higher-end Indian cloths (calicoes, muslins) competed with British ersatz in the colonial American market. Market shares just before the Revolution:

[Source: Styles (2016)]

The American colonists had higher incomes than Britons in the quarter century before the war of independence, so it’s entirely possible there was a bigger appetite for luxury goods in America than in Britain at the same time.

Finally, the purchase prices of Indian cloths faced by the East India Company showed a rising trend over time.

[Source: Gupta in Riello & Roy. The rising trend may be explained by a combination of the distingration of the Mughal empire and El Niño climate events, both of which could have reduced agricultural productivity in India. See Clingingsmith & Williamson 2008.]

Rising prices would have been an enhanced incentive for British firms to supply more cloth — with or without the Calico Acts. At the same time, Gupta also presents data from van Zanden for Amsterdam sales prices of Indian cottons with no trend over the same period. This suggests declining markups for the East India Companies.

Riello observes that the elasticity of substitution between cottons and other textiles could be quite high:

Riello’s note 34 is to Chaudhuri (1978), which is also worth quoting:

LikeLike

Textile Printing

(1)

Even before cloth production was mechanised starting in the 1770s, printing had been a capital-intensive branch of the textile industry with quasi-factory organisation, scale and agglomeration economies, and learning-by-doing.

But it’s easy to exaggerate its importance. Although finishing added 1/3 to 1/2 of the value in printed cloths, as late as 1818 printed cloths accounted for only ~5% of British home consumption of imported raw cotton and ~10% of exports [Harley (1998) pg. 72].

Although matching Indian quality may have been a big profit incentive for some Lancashire firms, the ability to produce an all-cotton cloth per se was certainly not dependent on technical learning in printing. To the contrary, while Europeans certainly stole many Asian techniques in dyes and mordants, the mechanisation of printing ultimately borrowed from, you guessed it, the paper-printing industry.

(2)

Besides, ‘ordinary’ market forces were already creating incentives to set up printing operations in Britain even without legislation.

The first Calico Act of 1700 had required that any printed cotton cloth sold in Britain had to be printed in Britain. This effectively meant the British East India Company was forced to import white Indian cloths for printing in London, rather than import cloths already printed in India. Therefore, between 1701 and 1721, when the second Act banned most cotton cloths, a substantial textile printing industry emerged in London.

Parthasarathi attributes to this 20-year phase the birth of the British textile printing industry.

However, Nierstrasz (pp 155-8) observes British and Dutch East India Companies faced strong incentives for locating printing operations in Europe anyway:

This seems borne out in the data presented by Riello:

Besides, the free-trading Dutch Republic was also a major centre of calico-printing.

So perhaps the 1700 legislation in Britain only reinforced a business incentive for cost-saving that was either preexisting or would have existed eventually anyway.

LikeLike

Knowledge Externalities

Parthasarathi argues there were no technological differences between India and Britain when it came to cotton; if anything, India was more advanced because Indian hand spinners possessed the skill to spin cotton warp. One should not anachronistically overstate the importance of specialisation specifically in the cotton-linen proto-industry. Learning and innovation easily flowed between textile sectors, and Britain was far ahead of India in every other kind of textile technology.

Here are some knowledge spillovers into the future cotton industry:

The gig mill for creating nap on wool, but eventually used in fustians. {Source}

{ book/paper printing —> textile printing }

{ “over 100 production innovations in fustians”

source}{{{ The carding engine: according to Allen’s calculations, the switch from hand-carding to machine-carding reduced the production cost of cotton yarn as much as spinning machines! Stages prior to actual spinning (including cleaning & roving but particularly carding) added almost as much value as spinning itself, and those costs were reduced just as much as spinning between 1760 and 1784 }}}

LikeLike

Miscellaneous

(1) Farrell (2016) documents the smuggling of prohibited calicoes based on data from seized contraband in the 18th century. But a priori you would think these were the higher-priced articles, and the fibre content analysis of foundling swatches in Styles (2016) does suggest ‘ordinary’ people weren’t in possession of smuggled Indian cloths.

(2) Broadberry & Gupta (2009) analyse the evolution of Anglo-Indian differences in production costs and productivity in cotton textiles from the late 17th century to the early 19th. But they do not observe price differences directly. They do a very rough approximation of cost differences using a geometric index of total factor productivity with three key inputs — raw material, labour, and capital. (a) Their exercise assumes all-cotton fabrics, and linen yarn was always cheaper. (b) We also now know from Humphries & Schneider (2016) that spinning wages were much lower than those Broadberry & Gupta have culled from the secondary literature.

(3) Griffiths, Hunt, & O’Brien (2008) argue that it was the combination of the Calico Acts and the Parliamentary promotion of Celtic linen which led to the famous cotton-related inventions of the Industrial Revolution. The Calico Acts had effectively required the warp of printed ‘cottons’ to be linen. But Parliament also promoted linen weaving in Ireland and Scotland for export, which created a scarcity of the linen yarn imported by English manufacturers for the ‘cotton’ cloths. The ‘upward drift’ in linen yarn prices induced Lancashire to seek substitutes — which created an incentive to build machines which could spin cotton warp. This is a kind of biased technical change argument, but the trouble is GHO doesn’t present relative prices of cotton and linen yarn. Linen yarn prices were rising, but so was cotton yarn. The GHO story needs the price of linen relative to cotton to be rising. The data from Styles (2016) are incomplete, but there doesn’t seem to be much there to support GHO:

(4) Griffiths, Hunt, & O’Brien (1991) argue the merit of the Calico Acts contrasts with the free-trading Dutch Republic, which never developed a serious cotton industry before the 19th century. But local Dutch manufacturers also made and exported cotton-linen cloths (bombazijn; see Davids p 154, 222-3; Vries & van der Woude p 291). Besides, the Dutch would be cut off from global markets by military defeats and shut out of European markets by national protectionism. Their overseas empire was not very extensive, and their domestic market just wasn’t that big. In a world of militarist-mercantilist cut-throats, strategic trade probably made more sense, simply to preserve as many industries as you could. But the Dutch didn’t do too badly anyway — they remained richer than England well into the 19th century.

LikeLike

Pingback: Tariff Protection of British cotton 1774-1820s | pseudoerasmus

Amazing. I think you do set a record straight here. Cottons weren’t “protected” by the Calico acts or the various sumptuary laws, woolens and silks and linens were. My view has been that the protections could not survive growing population pressures, changing tastes, or – father out – mouth-watering opportunities for export profits, but they were strong enough to force cotton for 50-70 years onto a different (though not necessarily new) domestic track, along which it did quite well. Up to now the only word I had for this track was “fustians” – now there is a lot more to think about.

When one of your posts sent me off on this fox-hunt a couple of years ago, O’Brien, et. al. (1991) was one of the first really useful papers I encountered. Nice to see the nod to it here.

Finally, someone should warn any innocent that might consider trolling “at the intersection of endogenous growth theory, strategic trade theory, and economic geography”: if you pitch a tent there, you are going to get hit by a bus!

LikeLiked by 1 person

O’Brien et al. (1991) is a really great paper, one of the best things I’ve ever read on the (historical) political economy of protectionism. And the small part at the end where they argue the crucial role of Calico Acts is really not essential to the paper.

Two things about this post: (1) I am struck by how little is actually known about an industry which has been the object of so much scholarly attention. (2) I got to call historians ‘Whiggish’ !

LikeLike

Interesting (and pretty comprehensive). I’ve only just had a chance to read this. Much of it I agree with; some of it I don’t. Having already commented today on one of your previous blog posts, I’ve only got time for three general comments.

(1) No-one who has worked on 18th century economic legislation would argue that passing the ‘Calico Acts’ had anything much to do with fostering an infant cotton industry. They were all about protecting the English worsted and silk manufacturers, while avoiding any encouragement to Jacobitism in (linen-manufacturing) Scotland and Ireland, and limiting damage to the East India Co. So if they encouraged technical innovation (which I agree is a big IF), it was more by luck than design.

(2) The rapid growth in output of the new cotton-linen fabrics – printed cottons (ie cotton-linens) and cotton (ie. cotton-linen) checks – came only after 1750 (as you say, it is possible to generate data). Rapid growth in consumption of cotton stockings (pleased to see you emphasize cotton stockings) had to wait until the Derby rib attachment at the end of the 1750s (cotton is a relatively inelastic fibre, meaning non-ribbed stockings sagged). Consumption of the old heavy fustians expanded less quickly, despite Wadsworth and Mann’s highlighting cotton velvet (cotton velvets were expensive). So the burst of mechanical innovation in the 1760s came pretty promptly after a marked expansion in output of the newer cotton-linen and cotton products. How much this owed to exports as opposed to the domestic market, or to one of these products rather than another, is a whole other issue.

(3) Within less than two years of Arkwright starting production at his first, Nottingham factory at the end of 1772 the act of parliament prohibiting printed calicoes was repealed. This suggests that once a British mechanical technology to spin cotton warps was perfected, legislators were willing to encourage it (though continuing to tax what they regarded as a luxury). An obvious counterfactual question follows – if Lewis Paul’s machine had worked as well, would legislators have done the same in the 1740s? Or, to put it another way, was it the Calico Act that inhibited technical innovation before 1760, or simply the failure of the inventors and their backers to make an appropriate mechanical technology work?

LikeLiked by 1 person

Thanks for the comments!

“No-one who has worked on 18th century economic legislation would argue that passing the ‘Calico Acts’ had anything much to do with fostering an infant cotton industry. They were all about protecting the English worsted and silk manufacturers, while avoiding any encouragement to Jacobitism in (linen-manufacturing) Scotland and Ireland, and limiting damage to the East India Co. So if they encouraged technical innovation (which I agree is a big IF), it was more by luck than design.”

I did not mean to say anyone has ever argued there was a deliberate policy of infant industry promotion of cotton. O’Brien et al. (1991) makes it pretty clear the “Calico Acts” were a by-product of bargaining amongst competing interests which accidentally ended up promoting cotton. Perhaps my meaning was not clear in the text, but I did mention agitation by wool and silk. ( I will add a note to clarify.)

(Actually, from economists’ point of view, the fact that legislation did not specifically intend to benefit cotton makes it a ‘clean’ case of infant industry protection.)

LikeLike

“This suggests that once a British mechanical technology to spin cotton warps was perfected, legislators were willing to encourage it…. An obvious counterfactual question follows – if Lewis Paul’s machine had worked as well, would legislators have done the same in the 1740s? Or, to put it another way, was it the Calico Act that inhibited technical innovation before 1760, or simply the failure of the inventors and their backers to make an appropriate mechanical technology work?”

It’s a very good point and I agree both hypotheses are plausible. But this post is largely reacting against the presumption that the Calico Acts promoted technical innovation.

“So the burst of mechanical innovation in the 1760s came pretty promptly after a marked expansion in output of the newer cotton-linen and cotton products. How much this owed to exports as opposed to the domestic market, or to one of these products rather than another, is a whole other issue.”

But I think that IS one of the key issues. Unless it was obvious ex ante to any potential inventor that the Calico Acts would be repealed given the right invention, then, otherwise the Calico Acts did diminish the potential size of the market. And growth in the demand for cottons had to await the growth of the export markets during the latter half of the 18th century.

LikeLike

Very interesting post! Indian cotton may not have been competitive cost wise as it was very labor intensive. The superior quality and the complexity of designs may have left it as a potential competitor. But then again what confounds me is if the Indian cottons were not competitive then why did the Brits resort to chopping off hands of Indian weavers to root out competition. And if the British textile industry was able to produce goods cheaper why was it so much worried about costly fancy fine cotton from India? What makes more sense is the need to ensure raw material supplies for the mills in England from colonies may have led Britain to destroy labor intensive textile industry there. The destruction of indigenous textile industry then increased the price of cloth so produced. That in turn presented colonies as a readymade market for the machine made clothing allowing mills in England to achieve scale economies. Have you come across any papers that delve into this angle?

LikeLike

British cloths were not competitive with Indian cloths until probably 1820 (for coarse cloths) and probably 1830 (for finer cloths). Before that, Britain was selling machine-spun yarn to Indian weavers, who became more competitive as a result of using British instead of Indian hand-spun yarn.

They did not. Lancashire drove Indian spinners completely out of business. But hand weavers survived. They still survive today!

Britain did not import too much raw cotton from India. Before the American South became the major source after 1800, it had been Brazil and the Caribbean.

Indian cotton is short-staple (at least before longer-staple cultivars were produced in the 20th century), so hand processes were best suited to making cloth from Indian cotton.

LikeLiked by 1 person

Pingback: The Calico Acts: Was British cotton made possible by infant industry protection from Indian competition? | History on the mysteryStream

I”m just stumbling into this so please forgive my ignorance. We know that the Brits at least threatened tradtional blacksmiths in Kenya and Uganda with amputations so that people would be forced to buy iron and steel implements made in UK. We’re also asking ourselves why there is no indigenous hand ginning, spinning and weaving tradition in the cotton growing areas of Northern Uganda where we come from and western Kenya where we live. We know kids who made toy spindles in the 1940s in Uganda but never went farther than that. Were spinners/weavers under similar threat as the blacksmiths. AND – what about African American hand textile production on the slave plantations of the South. What was happening there? Any info/references etc will be greatly apreciated. We both teach design at the TEchnical University of Kenya. We’re also on Academia.edu under the name Donna Pido

Best regards

Odoch and Donna Pido

LikeLike

Can you say anything (or point to bibliography) about the 1831 repeal?

LikeLike

Pingback: Chintz : The story of a luxury cloth from India – Paperclip.

Pingback: Globalization's Horrifying Ties to Western Colonialism